Maintenance

We use a very high-quality rope with a very tight lay, which mitigates most of the problems that can occur with a softer rope, and the Dyneema core is much less prone to any problems compared to a steel wire cable.

Moves that twist against the lay (the direction the rope is twisted) or with the lay will affect the rope. Twisting moves can cause the rope to birdcage at the splice or make the bar uneven when one rope is twisted and raises slightly.

If you twist with or against the lay, you need to count the rotations, and then twist back in the opposite direction to return to level.

If you are twisting/wrapping the ropes often you will need to be aware of this and tighten/loosen the lay of the rope accordingly.

Hockling is a problem with cable core trapezes. It is the visible looping and poking through of the inner cable. This should not happen with our ropes due to the very tight lay of the 4-strand rope and the Dyneema core being much more flexible, with no lay of its own (unlike steel cables).

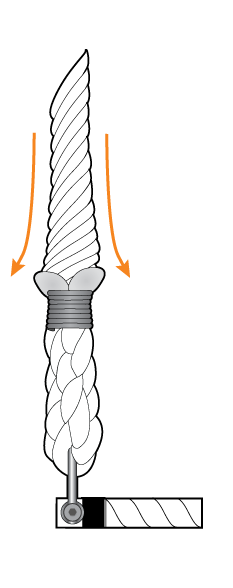

Over time the cotton rope can bunch towards the bottom splice. This is because the cotton rope has more stretch than the internal Dyneema core.

Any of these problems can be fixed and avoided by regular ‘Milking’ of the trapeze ropes. This descriptive, but unfortunately named, process involves pulling the rope up from the bar towards the top and should be considered part of the regular maintenance of the trapeze, being done approximately every 30 hours.

You can periodically remove the ropes and reverse the orientation, making the bottom of the rope the top of the rope. You need to take great care when removing/reinserting the carabiners not to snag the individual strands. You need to take great care that you reinsert the connectors through the steel thimble on the Dyneema core. We recommend that you do this as infrequently as possible.